Sugar Talk

Sugar Talk

What is the difference between beet sugar and cane sugar?

Understanding the difference between beet and cane sugars matters. This article explains where the crops grow, how they are milled and refined, what industrial sugar ingredients each source can make, and – most importantly – when they perform differently in your food and beverage recipes and pharmaceutical formulations. Crucially, many cane‑based sugar ingredients, especially those that retain molasses or are less refined, deliver functional properties that white crystalline beet sugar cannot replicate.

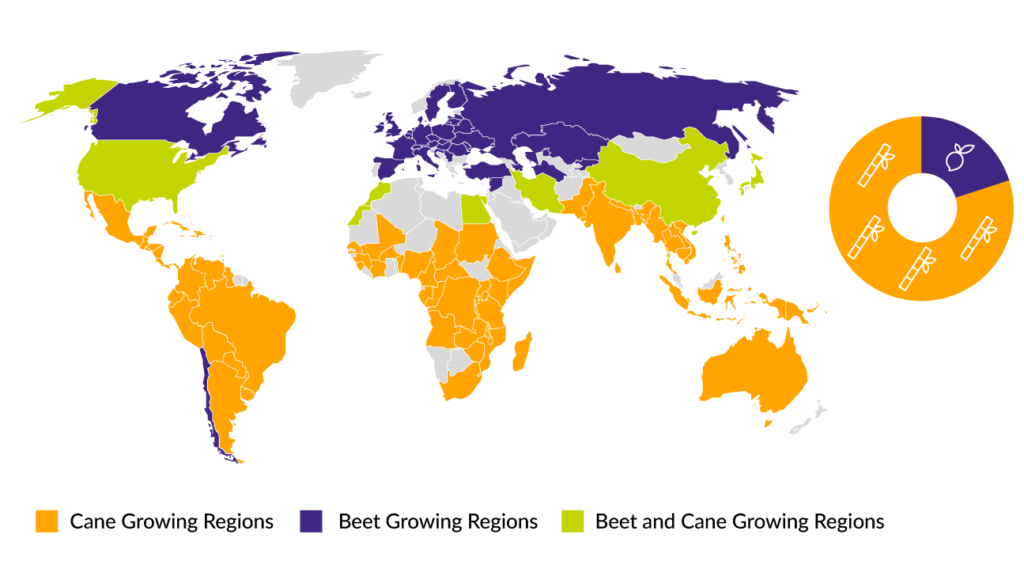

Mapped: where beets and cane thrive

Sugarcane grows in tropical and subtropical zones with abundant sunshine and rainfall. It is a tall perennial grass whose sucrose is stored in the stalk, produced by photosynthesis in the leaves before being transported down the stem. In 2023, global sugarcane output topped two billion tonnes, dwarfing the roughly 281 million tonnes of sugar beet harvested that year. FAO data confirms this dominant split.

Major sugarcane producers include Brazil, India, Thailand, Mexico, Pakistan, Mauritius, Laos and Australia. As a rule of thumb, sugarcane and the sugar ingredients that come from the plant account for most of the world’s sugar production and consumption. Beet sugar plays a larger role in temperate mostly northern hemisphere regions. Data from the International Sugar Organization (ISO) confirms that around four‑fifths of the world’s sugar comes from cane and one‑fifth from beet.

Sugar beet thrives in temperate climates. It is a biennial root crop with sucrose concentrated in the taproot, typically about 18% by weight at harvest. In Europe, most beet is grown in the northern half of the continent with competitive areas in northern France, Germany, the Netherlands, Belgium and Poland, and also in Russia and Ukraine. In the United Kingdom, beet is grown and refined largely in East Anglia and the East Midlands.

These growing patterns shape supply chains. Cane sugar is heavily traded internationally and often milled near farms before raw sugar is shipped for refining at coastal refineries. Beet sugar supply is more regional: factories are located close to fields and operate seasonally during the harvest or ‘campaign’, with short farm‑to‑factory distances reducing primary transport needs. Sugarcane and cane sugar dominate global output, but beets and beet sugar anchor Europe’s supply.

From field to crystal: how beet sugar and cane sugar are milled and refined

Although refined beet and refined cane white crystalline sugars are both pure sucrose, the journey from plant to crystal differs. At the sugarcane mill, harvested stalks are washed, cut and shredded, then crushed to extract juice.

The juice is heated and clarified, concentrated by evaporation and crystallised, with the massecuite syrup spun in centrifuges to separate raw sugar crystals from the syrup. The raw sugar is then dried and shipped for further refining, or, where facilities exist, refined on site.

Beet refineries follow a different sequence. Whole beets are washed and sliced into thin strips, or cossettes, then flowed into a diffuser where the beet is immersed in hot water for approximately one hour. Sucrose is extracted through an agitating process, whereby the sliced beet moves from one end of the tank while the water moves in the opposite direction. The longer this process lasts, the stronger the solution it creates, and what remains is referred to as juice. After purification and evaporation, crystallisation produces the final white sugar. Beet sugar refining produces molasses as a by-product, but beet molasses is very bitter and not palatable, so is used for animal feed, fermentation and yeast production.

When processed correctly, the white crystalline sugar from beet is chemically indistinguishable from white crystalline sugar refined from cane.

Sugarcane processing also yields characteristic intermediate and by‑products with functional value for industry. Less refined crystalline sugars such as demerara and muscovado, plus syrups like black treacle and cane molasses, are made from cane streams.

These process differences set up the ingredient landscape explored next: beet primarily delivers refined white crystalline sucrose at scale; cane can deliver that too, but also unique less‑refined crystalline sugars and syrups that influence colour, flavour and other functional properties essential for food and beverage and pharmaceutical brands.

What you can and cannot make with beet sugar and cane sugar

White crystalline sugar from beet is a highly versatile base and can be used to manufacture many essential functional sugar ingredients. White crystalline sugar refined from sugarcane can do the same. However, certain sugars and syrups depend on less‑refined cane streams or on cane molasses. Below is a quick guide with links to product pages.

Functional sugar ingredients that can be manufactured from beet based white sugar include:

Invert sugar syrup: A fully inverted sucrose syrup offering higher perceived sweetness and humectency than sucrose. Used to control crystallisation and improve softness in fondants, icings, confectionery and frozen desserts. Learn more.

Partial invert, like golden syrup: A partially inverted syrup with a distinctive amber colour and mellow caramel notes. Performs like other invert syrups but also contributes flavour and colour in biscuits, desserts and flapjacks.

Liquid sugar: A standardised sucrose solution for easy dosing in beverages, bakery and dairy. Acts as a clean label sweetener, bulking agent and fermentation aid in brewing and cider.

The above sugar ingredients can also be manufactured using white sugar refined from sugarcane. However, there are industrial sugar ingredients that can only be made from less‑refined cane streams or cane molasses:

Demerara crystalline sugar: Typically large, amber crystals with mellow molasses notes. Ideal for toppings, crunch and visual appeal in bakery and desserts. Demerara sugars can also be used as the base for demerara syrups.

Muscovado crystalline sugar and syrups: Soft, moist cane sugars naturally high in molasses. Light and dark grades give deep colour and complex flavour to sauces, cakes and marinades. Ragus blends both light cane muscovado and dark cane muscovado crystalline sugars and specially formulated muscovado syrups for specialist applications.

Cane molasses: A by‑product of cane sugar refining used for flavour, colour and humectency; fundamental in brewing, sauces, marinades, baking, confectionery and as a base for many other ingredients, such as treacles, crystalline cane sugars, cane syrups and soft brown sugars. Learn more about our molasses.

Black treacle: A syrup manufactured by blending refiner’s syrup, a fully inverted sugar syrup, with cane molasses to deliver bittersweet complexity, colour and moisture retention in baked goods, desserts and brewing.

Soft brown sugars (light and dark): Refined white crystalline sugar blended with refiner’s syrup and treacle to deliver colour, flavour and moisture. Widely used across baking, desserts, biscuits, sauces and confectionery. The light and dark varieties have varying levels of molasses resulting in different functional properties. Soft brown sugars can be made from both beet white sugar and cane white sugar, with added cane molasses.

White crystalline sugar refined from cane is virtually indistinguishable from refined white beet sugar. However, many less‑refined cane sugars and cane molasses are essential to create the full palette of colour, flavour and other functional properties discussed in the next section.

When to choose beet sugars or cane sugars as functional ingredients

Sugar has many functional properties beyond sweetness. In bakery, confectionery, beverages and pharmaceuticals, sugars drive browning, colour, flavour development and water retention for freshness, microbial stability for extended shelf life; they bulk, bind, control crystallisation and set texture; and they fine‑tune mouthfeel.

Caramelisation and the Maillard reaction create complex flavour and colour in baked goods and syrups, and both beet and cane derived white sugars can be used to create formulations using these processes. However, cane‑derived syrups such as black treacle and formulations containing cane molasses contribute distinctive colour palettes and flavour notes that beet‑only systems cannot deliver.

Functionally, sugars act as natural bulking agents and binders, influence viscosity and freezing point, and reduce water activity to extend shelf life. These roles underpin everything from ice cream scoopability to soft fondants, chewy biscuits and stable sauces.

For certain high‑specification applications—such as pharmaceutical syrups, premium confectionery or specialist refiners’ syrups like golden syrup—manufacturers often specify white crystalline sugar refined from sugar cane as the feedstock.

In these contexts, the ultra‑clean flavour profile and thermal behaviour demanded by the end product can be affected by the origin of the sucrose. Where consistency of colour, flavour and aroma is critical, cane‑refined white sugar is the industry norm, with cane molasses‑based ingredients providing further functionality where needed.

Industrial sugar ingredients are also plant‑based and typically qualify as clean label. Selecting the right combination of refined white sugars made from beet and cane, less‑refined cane sugars and syrups enables food scientists to formulate products that deliver exactly the target performance for the final product.

Beet and cane both deliver high‑purity sucrose at industrial scale, and for many applications refined white sugar from either source can be used interchangeably.

However, there are meaningful differences in where and how the crops are grown, the way mills and factories process them, and the ingredient portfolios they enable. Beet routes excel at efficient regional production of refined white crystalline sugar; cane routes deliver that too, but uniquely provide less‑refined crystalline sugars and molasses‑based syrups that contribute colours, flavours, textures and other functions that are difficult or impossible to replicate using beet‑only systems.

Ragus manufactures functional pure sugar ingredients for industrial food and beverage and pharmaceutical applications, enhancing flavour, texture and appearance. For guidance on choosing between beet‑derived and cane‑derived sugar ingredients for your next formulation, contact our Customer Services Team. For more sugar news and Ragus updates, keep browsing SUGARTALK and follow us on LinkedIn.