Sugar Talk

Sugar Talk

What’s the difference between partial and full invert sugar syrup?

Invert sugar syrups are essential functional ingredients across food, beverages, and pharmaceutical manufacturing. But not all inverts behave the same. The key distinction is between partially inverted sugar (sometimes called partially inverted refiners syrup) and fully inverted sugar syrup. They differ in composition, processing method, sweetness, functional performance, stability, and final applications. This guide explains those differences in detail, helping you select the right invert for your formulation.

Why understanding the difference matters

Although both syrups start with sucrose and involve the same fundamental chemical change, the inversion of sucrose into glucose and fructose, partially inverted and fully inverted sugar syrups can serve very different functional roles in manufacturing.

- Fully inverted sugar syrup is intensely sweet, highly hygroscopic, resists crystallisation and improves texture and moisture retention.

- Partially inverted sugar syrups, such as premium golden syrup, offer greater stability at high baking temperatures, provide desirable colour and flavour, and have a different balance of sucrose and inverted sugars, giving manufacturers more control over sweetness, viscosity and browning.

Choosing the wrong type can affect sweetness, shelf life, humectancy, texture, colour, freezing point, and processing behaviour. Understanding the difference ensures the correct ingredient for the desired performance.

What is fully inverted sugar syrup?

Fully inverted sugar syrup is a single-stage liquid sugar produced when sucrose is completely inverted, or hydrolysed, into its two component monosaccharides: glucose and fructose. Ragus manufactures fully inverted sugar syrups with a consistent Brix (a measure of dissolved solids in a liquid, in this case sugar) and tight control over colour and purity. This syrup delivers:

- Intense sweetness with a higher perceived sweetness than sucrose.

- Outstanding humectancy, or moisture retention.

- Improved texture and softness.

- Resistance to crystallisation.

- Lower water activity for improved shelf life.

- Viscosity that aids processing.

Fully inverted sugar syrup is commonly used in bakery, confectionery, soft drinks, frozen desserts, brewing, and pharmaceutical syrup formulations. It is available in cane or beet formats and in organic options.

What is partially inverted sugar syrup?

Partially inverted sugar syrup contains a blend of sucrose and inverted sugars. It is produced through a two-stage process designed to stop the inversion before it reaches 100 percent. This balance gives partially inverted sugar syrups unique functional properties.

A widely recognised example is golden syrup, which has:

- A characteristic amber colour.

- A clean, rounded caramel-like flavour.

- Higher thermal stability than fully inverted sugar syrup.

- A viscosity that makes it an attractive topping and baking ingredient.

- A balanced sweetness profile.

- Good humectancy and freezing point depression.

Premium golden syrup, and other high-quality partially inverted refiners syrups, are generally made from cane sugar, although partial inverts can technically be produced from both cane and beet.

As with full inverts, organic versions can be produced.

How are they made?

Fully inverted sugar syrup:

- Single-stage process.

- Sucrose solution is heated and inverted using acid or enzyme catalysis.

- Inversion continues until the sucrose is fully hydrolysed.

- Typical Brix: high, consistent across production.

- Result: intense sweetness, high humectancy, smooth texture and reduced crystallisation risk.

Partially inverted sugar syrup:

- Two-stage process.

- Sucrose undergoes controlled inversion and is then stabilised before full hydrolysis.

- Retains a proportion of sucrose.

- Typical Brix: similar to full invert but with higher viscosity due to sucrose content.

- Result: desirable colour, flavour, controlled sweetness and thermal stability.

Both forms can be made using cane sugar or beet sugar. However, premium golden syrup, the benchmark partially inverted refiners syrup, is often cane-derived.

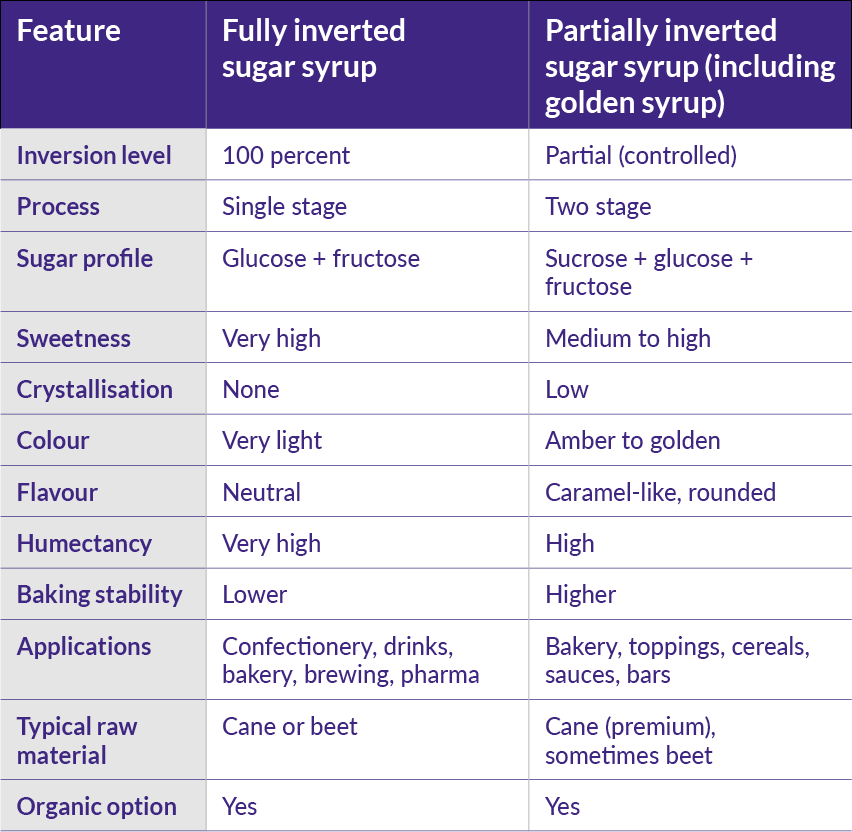

Quick comparison table

Applications by category

Both partially and fully inverted sugar syrups are used across a wide range of food, beverage and pharmaceutical applications. Choosing the right syrup ensures the right functionality and desired outcome for your end-product.

Bakery and biscuits, including patisserie

Invert sugars are widely used in bakery for their ability to retain moisture, delay staling and enhance softness.

- Fully inverted sugar syrup adds intense sweetness, improves crumb tenderness, and enhances shelf life through humectancy.

- Partially inverted sugar syrup, such as golden syrup, withstands higher baking temperatures, provides caramel notes, supports browning, and helps achieve consistent viscosity in doughs and batters.

Applications include sponge cakes, biscuits, pastry glazes, frangipane, enriched doughs and patisserie items.

Desserts, toppings and ice cream

In frozen desserts, invert sugars are particularly valuable because fructose depresses the freezing point, improving smoothness and reducing ice crystal formation.

- Fully inverted sugar syrup is ideal for ice creams, gelato, sorbets, mousses and dessert sauces.

- Partially inverted sugars add colour, flavour, and a controlled sweetness profile for toppings, puddings, and spoonable desserts.

Sauces, syrups and marinades

Both inverts improve viscosity, stability and mouthfeel in syrups and sauces used across food manufacturing and breakfast products.

- Partially inverted sugar syrups are widely used for pancake syrups, porridge toppings, fruit sauces and marinades.

- Full invert is favoured when a clean flavour and high sweetness are required with no crystallisation.

Breakfast cereals and bars

Invert sugars act as effective binding agents, coatings and humectants.

- Fully inverted sugar syrup is ideal for cereal coatings requiring sweetness and gloss.

- Partially inverted sugars deliver colour, viscosity and structure, making them suitable for granola clusters, cereal bars, high-energy bars, and muesli binders.

Confectionery

Both Syrups are widely used in soft and chewy confectionery due to their ability to manage crystallisation and sweetness.

- Full invert supports soft caramels, fondants, jellies, liquorice, and toffees by preventing crystallisation.

- Partial invert contributes viscosity, flavour and temperature stability for toffees and fudge.

Soft drinks

Fully inverted sugar syrup is widely used in soft drinks, energy drinks and flavoured beverages due to:

- Dissolution speed.

- Sweetness intensity.

- Colour neutrality.

- Microbial stability.

Partially inverted sugar syrups can be used in craft beverages and speciality drinks where flavour and colour contribute to brand identity.

Brewing

Invert sugar is a traditional ingredient in British and Belgian brewing.

- Fully inverted sugar syrup delivers fermentable glucose and fructose, supporting alcohol production and dryness.

- Invert sugar syrup made from white sugar is a light colour low viscosity liquid with high sweetness value, but as the monosaccharides ferment into alcohol, there is no residual sweetening of the beer, cider or perry.

- Partially inverted sugar syrups, including golden syrup, deliver colour, subtle caramel notes, and high fermentability.

They also reduce stress on yeast and improve consistency in high-gravity brewing.

Pharmaceutical

Invert sugars play essential roles in medicinal syrups, suspensions and oral formulations.

- Fully inverted sugar syrup contributes sweetness, stability, humectancy and helps achieve a smooth mouthfeel.

- Partially inverted sugar syrups can be used when a gentler flavour or colour is preferred.

Applications include cough syrups, vitamin syrups, elixirs and paediatric formulations.

Nutrition and sports products

Manufacturers use invert sugars for:

- Rapid energy release.

- Improved texture.

- Binding of sports bars and nutrition gels.

Partially inverted sugar syrups give products body and warmth, while fully inverted syrups deliver fast-acting carbohydrates.

Practical specification tips

When choosing between partially inverted sugar syrup and fully inverted sugar syrup:

1. Define the target sweetness level

Full invert offers higher perceived sweetness due to higher fructose levels.

2. Map thermal stability requirements

Partial invert withstands higher baking temperatures.

3. Consider crystallisation behaviour

Fully inverted syrup can prevent crystallisation entirely.

4. Determine required viscosity

Partially inverted sugar syrup typically offers higher viscosity.

5. Check colour and flavour targets

Golden syrup partial inverts add amber tones and caramel notes.

6. Specify cane or beet

Particularly important for origin-sensitive and premium formulations.

7. Check Brix, inversion level and pH

Essential for process consistency.

8. Use organic options where required

Available for both full and partial inverts.

Common misconceptions

“Golden syrup and fully inverted sugar syrup are the same.”

No — golden syrup is a partially inverted sugar syrup with different flavour, colour and functional performance.

“Full invert is always sweeter.”

Not always — perceived sweetness depends on application, temperature and matrix.

“You can substitute one for the other directly.”

They behave differently in heat, moisture retention and crystallisation. Formulation adjustments are usually required.

“Partial inverts are only for baking.”

They are widely used across cereals, toppings, bars, confectionery and speciality beverages.

Responsible sourcing

Ragus manufactured invert sugar syrup ingredients using responsibly sourced cane and beet sugar. Cane-derived syrups underpin premium golden syrup, while beet-based syrups provide an alternative where origin or regional supply is important.

Raw materials are sourced through fully traceable global supply chains, ensuring quality, consistency and ethical standards.

Frequently asked questions

Golden syrup is a premium form of partially inverted sugar syrup made from cane sugar.

Not directly. It is sweeter and less thermally stable.

Yes, due to its humectancy and lower water activity.

Partially inverted sugar syrups, particularly golden syrup.

Yes — Ragus manufactures organic options.

Fully inverted sugar syrup.

Yes, though full invert is preferred for most beverages.

Yes — it is another name for a partially inverted sugar syrup.

Yes — they are plant-derived.

Fully inverted sugar syrup for freezing point depression and texture.

Key takeaway

Both partially inverted and fully inverted sugar syrups are valuable ingredients across the food, beverage, brewing and pharmaceutical sectors, but they deliver distinct functional benefits.

Fully inverted sugar syrup offers intense sweetness, humectancy and crystallisation control. Partially inverted sugar syrups, including golden syrup, provide heat stability, flavour, colour and viscosity. The right choice depends entirely on your formulation, processing conditions and desired product attributes.

Ragus manufactures high-quality, fully invert and partially inverted sugar syrups to consistent specifications at scale. To discuss which syrup is right for your formulation or request a sample contact our Customer Services Team. For more sugar news and Ragus updates, keep browsing SUGARTALK and follow Ragus on LinkedIn.

Ibrahim Belo

With a primary responsibility for manufactured product quality control, Ibrahim works within our supplier chain, factory and production laboratory. He has a focus on continuous improvement, implementing and maintaining our technical and quality monitoring processes, ensuring standards and product specifications are met.