Sugar Talk

Sugar Talk

Non‑alcoholic wine, beer and cider: how sugars and syrups rebuild properties after dealcoholisation

As demand for low and alcohol-free drinks grows, wine, brewing and cider brands face the challenge of replicating the flavour, body and balance that ethanol provides in these beverages traditionally. In this blog, we explore how sugar supports the reformulation of non-alcoholic wine, beer and cider, and why choosing the right sugar ingredient for each application is critical.

The growing market for non-alcoholic beverages in Europe

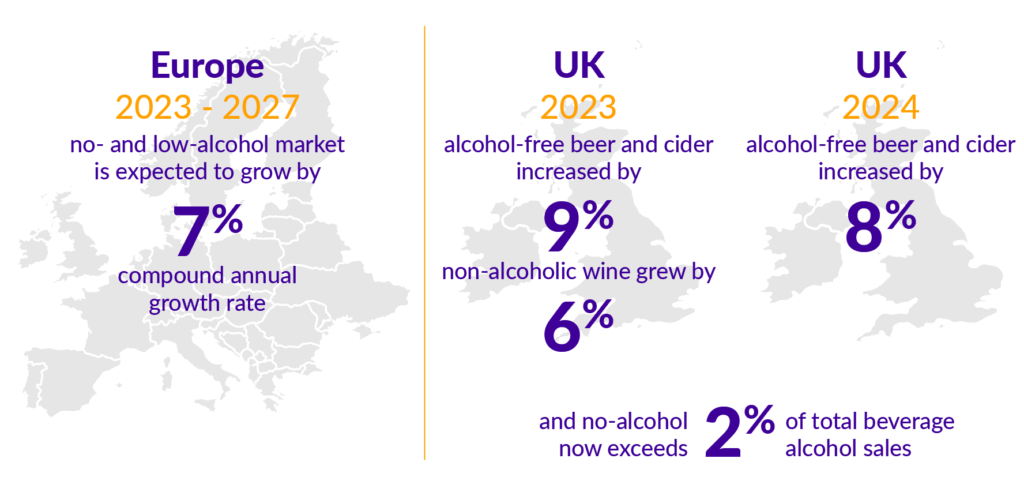

The non-alcoholic drinks market has grown rapidly in recent years, driven by shifting consumer preferences towards healthier lifestyles and mindful drinking. According to the IWSR (International Wine and Spirits Record), the no- and low-alcohol market in Europe is expected to grow by 7% compound annual growth rate (CAGR) between 2023 and 2027, with the UK being one of the largest markets.

In 2023 alone, IWSR’s data shows sales of alcohol-free beer and cider increased by more than 9% in the UK, while non-alcoholic wine grew by 6%, reflecting a strong consumer appetite for alternatives that deliver the same sensory experience without the alcohol. In the UK specifically, no‑alcohol wine grew +8% in 2024 and no‑alcohol now exceeds 2% of total beverage alcohol sales.

This creates opportunities for beverage manufacturers, but also technical challenges. Alcohol contributes body, mouthfeel and balance. When it is removed, drinks can taste thin or unbalanced, which is where sugar plays a vital role.

Why sugar matters when alcohol is removed

Ethanol does more than add warmth; it carries aroma, softens acidity and bitterness, and contributes to viscosity. Remove it and wines and beers can taste thinner, tarter or more bitter, with muted fruit. Reviews of wine dealcoholisation consistently note higher perceived acidity, reduced body and shifts in aroma intensity when ABV (alcohol by volume) is lowered.

Alcohol is removed from beverages through several methods. Vacuum distillation gently heats the liquid at low pressure, removing alcohol while attempting to preserve delicate flavours and aromas. Reverse osmosis filters alcohol molecules through a membrane, leaving behind water and flavour compounds that are later recombined. Spinning cone columns use centrifugal force to separate alcohol from the liquid in stages, allowing some aroma compounds to be captured and returned. Reverse osmosis tends to better preserve aroma than thermal methods; vacuum lowers boiling points to reduce heat damage.

While effective, all these methods also remove or alter compounds that contribute to body, sweetness perception and flavour. As a result, dealcoholised drinks can taste thinner and less balanced. Sugars and syrups are added not only for sweetness but also to restore mouthfeel, balance acidity, and improve flavour integration.

Depending on local winemaking and brewing regulations, winemakers can legally sweeten with grape‑derived materials, like rectified concentrated grape must, or approved sugars, which include dextrose, fructose, glucose syrup and inverted sugar syrup. Brewers typically add adjunct sugars, such as invert sugar syrups, golden syrup and treacle, pre‑fermentation to shape colour, body and flavour. For non‑alcoholic beers, they often also use non‑fermentable carbohydrates or pasteurisation to stabilise any post‑process sweetness, or prime with sugars.

When and how sugars are used in dealcoholised wines

Non‑alcoholic and dealcoholised wines are typically made via spinning cone columns, reverse osmosis or vacuum distillation after full fermentation. Removing ethanol increases perceived acidity and can thin mouthfeel. Phenolics and volatile aroma compounds can also be lost, with method‑dependent effects on fruit intensity and astringency.

The International Organisation of Vine and Wine (OIV) allows grape‑derived products to be sweetened with grape must concentrates and certain sugars, including inverted sugar syrup. What can be used is also subject to local regulations, which vary. For example, there are EU rules that specify formal categories for partially and fully dealcoholised wines, with specific labelling and practice/process constraints.

White and rosé dealcoholised wines often need a small sweetness adjustment to offset sharper acidity, whereas red wines may require careful management of tannin/astringency after alcohol removal. Invert sugar syrup is especially effective in non-alcoholic wine because it provides clean sweetness, body and mouthfeel that integrates seamlessly.

The benefits of functional sugar ingredients in non-alcoholic beer

In brewing, sugar is used during fermentation to influence flavour, colour and alcohol content. Non‑alcoholic beers are made either by limiting/almost‑stopping fermentation or by removing ethanol from a finished beer, via reverse osmosis or vacuum/thermal methods.

Limited‑fermentation beers tend to be sweeter and more ‘worty’; physically dealcoholised beers often taste thinner, with lower aroma intensity and can lose CO₂/foam if not carefully managed. After alcohol removal, brewers need to restore balance by adding sugar back into the liquid.

Invert sugar syrups are a common solution, providing fermentable sugars that restore body and enhance foam stability, helping to deliver the head retention consumers expect from beer. Although residual fermentable sugar post‑dealcoholisation as a priming sugar risks refermentation unless the beer is stabilised via pasteurisation or filtration.

Restoring flavour and fizz to low- and no-alcohol ciders

Cider is produced by fermenting apple sugars, creating natural alcohol with carbonation and balancing tartness with sweetness. Removing or restricting the alcohol alters the flavour profile significantly. The result can be a drink that tastes too sharp or thin.

Alcohol‑free ciders are made by arresting fermentation early or by removing alcohol from a finished cider through techniques such as reverse osmosis. Both approaches can affect acidity and remove aromas and flavour.

Cider makers typically restore flavour, or ‘back-sweeten’, balance acidity and re‑carbonate with apple juice concentrate or permitted sugars, usually liquid sugars and invert sugar syrups, or glucose syrups.

Sugar ingredients are a vital tool in the production of non-alcoholic wine, beer and cider. By restoring balance, flavour and body, they enable producers to meet consumer expectations for taste and quality whilst offering the low and no-alcohol benefits. With demand for no- and low-alcohol drinks continuing to grow in the UK and across Europe, sourcing the right sugar ingredient ensures that consumers continue to fully enjoy wines, beers and ciders without the alcohol.

Ragus manufactures functional pure sugar ingredients for industrial and craft beverage applications, enhancing flavour, body and mouthfeel. To learn more about our pure sugars, contact our Customer Services Team. For more sugar news and Ragus updates, keep browsing SUGARTALK and follow Ragus on LinkedIn.

Ben Eastick

A board member and co-leader of the business, Ben is responsible for our marketing strategy and its execution by the agency team he leads and is the guardian of our corporate brand vision. He also manages key customers and distributors.

In 2005, he took on the role of globally sourcing our ‘speciality sugars’. With his background in laboratory product testing and following three decades of supplier visits, his expertise means we get high quality, consistent and reliable raw materials from ethical sources.