Sugar Talk

Sugar Talk

Sugar as a shelf life extender

For food and beverage manufacturers, shelf life is a major challenge. A product that dries out, stales, loses flavour or colour, or becomes unsafe due to microbial growth is one that fails both customers and retailers. At the same time, maintaining a cold chain throughout the supply chain is energy-intensive and increases greenhouse gas emissions. Sugar offers a natural solution: it extends shelf life by retaining water, slowing crystallisation, inhibiting microbial growth and maintaining product quality at ambient temperatures.

This blog explains what shelf life is, why it matters, how foods spoil, the science of humectancy, and how sugar ingredients extend the life of foods, beverages and pharmaceuticals.

What is shelf life and why is it important

Shelf life refers to the length of time a food or beverage product can be stored before it is considered unsuitable for sale or consumption. It is closely linked to both food safety and quality.

From a safety perspective, ‘use by’ dates are critical: once this date passes, the product may no longer be safe to eat due to microbial growth or chemical changes. From a quality perspective, ‘best before’ dates relate to attributes such as texture, flavour, appearance and nutritional content.

Food and beverage manufacturers determine shelf life using scientific testing under controlled conditions, assessing how factors such as temperature, packaging, moisture and oxygen exposure affect product stability.

For brands, a longer shelf life reduces waste, ensures product reliability, and improves distribution efficiency. For consumers, it means consistent quality and confidence in the safety of their food.

How can food and beverages spoil?

Food spoilage occurs through a combination of physical, chemical and biological processes. Moisture loss is a key factor. In bakery goods, water migrates from the crumb to the crust, causing starch molecules to realign, a process called retrogradation. This leads to staling: bread becomes dry and firm and cakes lose softness. This physical change is a major limitation for shelf life.

Flavour and aroma also degrade over time. Volatile compounds that contribute to freshness dissipate, while oxidation can create off-flavours. Colour and visual appeal fade as natural pigments break down. Together, these changes mean consumers are less likely to accept a product even before safety is compromised.

The most critical cause of spoilage is microbial activity. Pathogenic bacteria such as Salmonella, Pseudomonas and E. coli, as well as yeasts and moulds, can grow rapidly in favourable conditions. Not only do they affect texture and flavour, but they also present serious health risks. This is why food preservation techniques are essential.

What is humectancy in sugar and why is it important

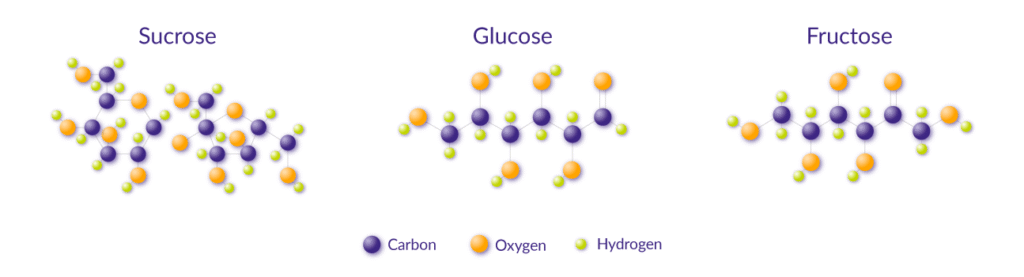

Humectancy is the ability of a substance to attract and hold water molecules. Sugars, particularly invert sugars, glucose syrups and fructose, are powerful humectants. In solution, sucrose molecules interact with water molecules via hydrogen bonding, reducing the amount of ‘free’ water available. Monosaccharides such as glucose and fructose are even more effective, binding water more tightly and preventing crystallisation.

By retaining water, sugars keep products moist and extend freshness. They also slow staling. In baked goods, sugar interferes with starch retrogradation, delaying the firming process that makes bread and cakes stale. This effect is essential for maintaining texture over time.

Sugars also inhibit microbial growth. By lowering water activity, they create conditions that are less favourable for bacteria and fungi. Invert sugars and syrups, for example, are commonly used in bakery and confectionery applications to achieve this effect. Sugars disrupt microbial enzyme systems, further limiting growth.

How sugar extends shelf life in food, beverage and pharmaceutical products

The role of sugar in extending shelf life varies by product category. In bakery and confectionery, invert sugars, glucose syrups and golden syrup are used to keep products soft, chewy and moist. For example, soft cookies rely on invert sugar to retain chewiness, while cakes remain moist for longer. Without these sugars, staling would occur more quickly, shortening shelf life.

In preserves, jams and sauces, sugars such as different crystalline sugars, liquid sugars and molasses lower water activity and prevent microbial spoilage. At the same time, they contribute to consistency and flavour. For sauces and savoury products, molasses and black treacle provide additional stability and colour retention.

In pharmaceuticals, sugar syrups are not just excipients but active functional ingredients. They act as stabilisers, prevent crystallisation, mask bitterness and ensure the stability of liquid formulations. They also provide energy and improve patient compliance by making medicines more palatable.

Other categories also benefit: dairy desserts use sugars to stabilise texture; confectionery relies on invert and glucose syrups to prevent crystallisation; and ready-to-drink beverages depend on liquid sugars for stability and consistency.

Sugar can mean no cold chain and no additives

One major advantage of using sugar in food and beverage formulations is that it extends shelf life at ambient temperatures. This reduces or eliminates the need for refrigeration during transport and storage, avoiding the energy use and greenhouse gas emissions associated with cold chains. For food and beverage manufacturers and retailers, this translates into lower costs and improved sustainability.

Another consideration is the reformulation trend, reducing the sugar content in recipes and replacing sugars with artificial sweeteners. If sugar is reduced or removed from industrial recipes, artificial preservatives are often required to maintain shelf life. This can push products into the ‘ultra-processed’ category, which many consumers are trying to avoid.

Using plant based, clean label pure sugar industrial ingredients instead offer a simpler, more label and consumer-friendly solution.

Extending shelf life is just one of the many functional properties of industrial sugar ingredients. From maintaining moisture to inhibiting microbial growth, sugars deliver far more than sweetness.

Ragus manufactures functional pure sugar ingredients for industrial food and beverage and pharmaceutical applications, enhancing flavour, texture and appearance. Contact our Customer Services Team to learn which of our pure sugar ingredients can best extend the shelf life of your application. For more sugar news and Ragus updates, keep browsing SUGARTALK and follow us on LinkedIn.