Sugar Talk

Sugar Talk

Life cycle assessments for sugar ingredients

How sustainable are your sugar ingredients? That’s the question food and beverage brands are asking as they seek to lower their environmental impact. Life cycle assessments (LCAs) offer the full picture. From cultivation to delivery, they reveal where carbon emissions occur, how resources are used, and what actions can reduce impact. In this blog, we explain what LCAs are, the stages of a sugar ingredient’s life, and how this knowledge helps food and beverage brands make more sustainable choices.

What is a life cycle assessment?

A life cycle assessment (LCA) is a scientific method for assessing the environmental impact of a product or process from start to finish – literally, from cradle to grave. For sugar ingredients, this means evaluating every stage of the journey: from crop cultivation, to sugar extraction and refining, to transport, manufacturing the ingredient that has the functional properties, and finally to when the consumer uses, or in this case eats or drinks, the final product.

LCAs are holistic and include multiple impact categories: greenhouse gas (GHG) emissions, water and land use, energy consumption, and more. To ensure consistency, they are standardised under ISO 14040 and ISO 14044. These standards define four phases of a typical LCA:

1. Goal and scope definition.

2. Life cycle inventory analysis.

3. Impact assessment.

4. Interpretation.

Organisations, including the stakeholders in the sugar supply chain, use LCAs to understand and reduce their environmental footprint. For food and beverage brands, they are essential for setting and meeting environmental targets and proving sustainability claims. They also feed into Science Based Targets (SBTs) – a framework that enables companies to set carbon reduction goals in line with climate science.

It’s important to distinguish between an LCA and a Product Carbon Footprint (PCF). A PCF focuses specifically on GHG emissions, whereas an LCA covers a wider range of environmental impacts. Together, they provide a full picture of a product’s sustainability profile.

The main stages of the industrial sugar ingredient lifecycle

What’s really behind your functional sugar ingredients? The life cycle of an industrial sugar ingredient includes all stages from sugarcane or sugar beet plant to plate. While sugarcane and sugar beet differ in how they grow and are processed, the stages of their lifecycle are broadly similar. These include:

– Cultivation – growing cane or beet crops using water, fertiliser, and energy inputs.

– Harvesting – cutting or lifting the crop.

– Milling or processing – crushing cane or slicing beet to extract juice.

– Refining – purifying raw juice into crystallised sugar or syrup.

– Transport – moving raw and refined sugar between stages, often from one part of the world to another.

– Ingredient manufacturing – creating specialist sugar ingredients, such as syrups or blends.

– Delivery – transporting the final industrial sugar ingredient to food and beverage brands’ factories and plants, where products are manufactured that consumers eat and drink.

– End use – inclusion in products consumed by people.

For LCAs, each of these stages must be analysed to calculate the total environmental impact. This includes energy consumed, emissions produced, water withdrawn, and land used. The process also identifies hotspots – stages that contribute disproportionately to the footprint, and where improvements will have the most impact.

GHG emissions – what are they and why are they important?

Carbon counts – and here’s why sugar buyers need to care about emissions. Greenhouse gas (GHG) emissions are one of the most important metrics in an LCA. GHGs include carbon dioxide (CO₂), methane (CH₄), and nitrous oxide (N₂O), all of which contribute to climate change. For sugar ingredients, emissions arise at multiple stages – from diesel-powered farm machinery to fertiliser application, factory energy use, and transport.

To quantify GHG emissions, LCAs follow internationally recognised standards, especially ISO 14067. This builds on the ISO 14040 family, which sets the general framework.

Emissions are reported across three scopes:

Scope 1: Direct emissions from owned operations (e.g. factory fuel use)

Scope 2: Indirect emissions from purchased electricity

Scope 3: All other indirect emissions (e.g. raw material sourcing, distribution)

Within Scope 3, emissions from agriculture (cultivation), processing, and distribution of sugar are critical. To support accurate calculations, businesses use emissions factors – standardised values that estimate emissions per unit of activity. For sugar raw materials that tends to be kg of CO2 produced per kg or per tonne of sugar product.

White crystalline sugars, or sucrose, manufactured in Europe from sugar beet harvested in Europe can be between 650-800 kgCO2e / tonne, depending on the specific supply chain and refinery efficiency. This means between 650-800kg of carbon dioxide or equivalent (meaning possibly other greenhouse gases) are emitted for every tonne of white sugar manufactured.

Calculating and reporting GHG emissions helps industrial sugar ingredient manufacturers and food and beverage brands track their carbon footprint and identify reduction opportunities. One key element of an LCA. It is also an essential step for those committing to Science Based Targets (see below).

FLAG – forest, land and agriculture

FLAG stands for Forest, Land and Agriculture – sectors responsible for nearly a quarter of global GHG emissions. In response, the Science Based Targets initiative (SBTi) launched FLAG guidance to help companies set land-sector-specific targets.

FLAG emissions matter in sugar production because they capture impacts not covered by traditional carbon accounting – such as soil carbon loss, land use change, and deforestation. For example, converting forest to sugarcane plantations increases GHG emissions. Conversely, improving soil health or adopting regenerative practices can reduce them.

FLAG assessments also include:

– Soil organic carbon loss or gain.

– Methane from burning crop residues.

– Nitrous oxide from fertilisers.

– Emissions from land use change, such as deforestation.

This is where regenerative agriculture comes in. It refers to practices that restore soil health, increase biodiversity, and improve ecosystem resilience – such as reduced tillage, cover cropping, and crop rotation. These techniques are increasingly important for sugar producers seeking to improve FLAG outcomes.

Brands and suppliers are now expected to disclose FLAG-related data and act on it. LCAs that include FLAG impacts give a more accurate and responsible view of a sugar ingredient’s footprint.

Beyond carbon: what else counts in a sugar LCA?

While GHG emissions are often the headline metric, a complete life cycle assessment considers many other environmental impacts. These include:

Water use – including irrigation during cultivation and process water in mills, refineries and factories.

Land use – the area needed to grow sugar crops and build facilities.

Fertiliser and pesticide use – with impacts on soil health and biodiversity.

Energy use – from milling and refining, machinery, factories, and transport.

Soil degradation – such as erosion or nutrient loss.

Biodiversity – the impact of monoculture and land clearance.

Waste generation – including bagasse, effluents, and packaging waste.

LCAs convert these factors into quantifiable metrics that can be tracked and compared. This allows sugar buyers and food brands to evaluate trade-offs and find the most sustainable sourcing strategy.

For example, one source may have lower carbon emissions but has much greater soil loss, while another generates higher emissions but contributes to soil health and biodiversity. Only by understanding the full picture can all the stakeholders in the sugar supply chain, including food and beverage brands, make informed decisions about their industrial ingredients choices.

How sugar ingredient LCAs give choices to the supply chain

LCAs offer a powerful tool for food and beverage brands, manufacturers, and ingredient suppliers. By understanding the total environmental impact of sugar ingredients – not just emissions, but water, land, biodiversity and more – stakeholders can:

– Choose lower-impact supply chains.

– Set and meet sustainability targets.

– Report with transparency and credibility.

– Reduce business risk from climate regulation or market expectations.

– Create a source of differentiation and competitive advantage.

Sustainable options often come at a cost. But the cost of not reducing your supply chain’s impact will be higher – through loss of reputation, compliance failures, or disrupted supply.

And many businesses have flipped their ESG programmes from cost centres to profit centres, successfully monetising their investment in more responsible and sustainable sugar ingredient supply chains.

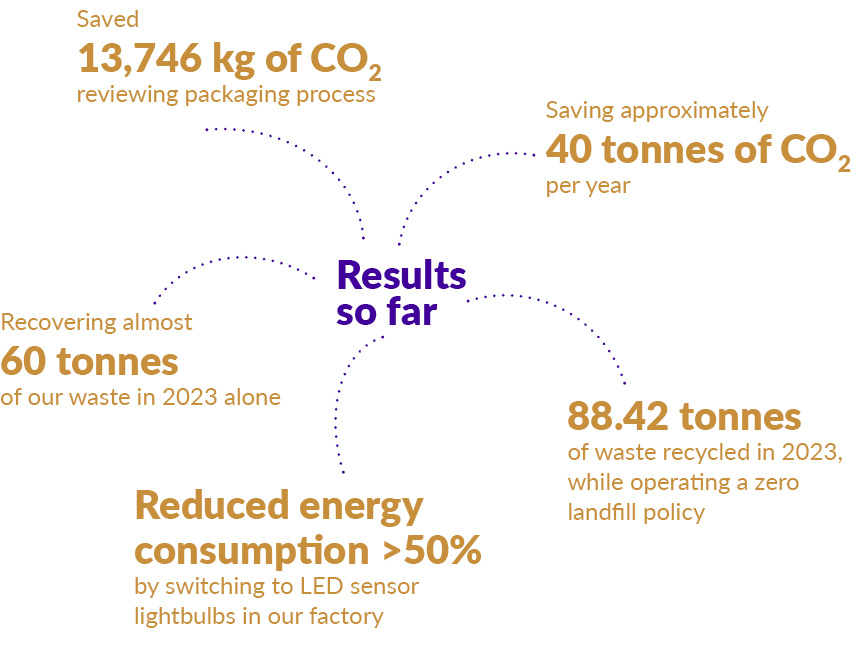

At Ragus, we are working to reduce the environmental impact of our products and offer our customers choices that enable them to both meet their ESG obligations and authentically use their supply chain choices as a source of competitive advantage.

That includes investing in our own processes and working with suppliers who share our values. You can learn more about our ESG approach on our website and in our latest ESG report.

If you want to understand more about how sugar ingredients impact your brand’s sustainability targets – and how we can help – contact our Customer Services Team. For more sugar news and updates, browse SUGARTALK and follow Ragus on LinkedIn.

Henry Eastick

Joining Ragus in 2017, Henry is the fifth generation of the Eastick family to work in the business. He has worked across our company, implementing plant and technology improvements in the factory to working in the lab developing a knowledge for our products. He focuses on our raw materials procurement as well as leading our digital transformation, adapting new technology and plant to meet our needs. His deep interest in nature and sustainability makes him a dedicated and passionate ESG manager.